Please, in order to enter to the members area fill in the boxes below this lines.

Please type your email address below and you will shortly receive an email.

Located in the Northwest of Spain, AIMEN Technology Centre is a highly professionalized organisation with over 220 employees specialised in Materials Science, Process Engineering, Automation, and Laser Processing. AIMEN is a non-profit private research association with more than 100 industrial members, established to increase the technological competence in the manufacturing industry, through the following activities: (i) R&D+i projects, (ii) Monitoring technology evolution, (iii) Acquire and develop emergent technologies, (iv) Promote technology innovation in the companies. Around 2/3 of all projects are in direct collaboration with the industry and around 1/3 of projects have the objective to search medium-long term industrial applicability. AIMEN participates in numerous regional, national R&D+i projects, and has an increasing presence in international research activities in photonics.

The Universitat Politècnica de Catalunya is a public institution dedicated to higher education and research, specialized in the fileds of engineering, architecture and science. The UPC is among the largest Spanish technical universities, with more than 2.600 researchers and 30.000 students, covering research in the all the main engineering fields.

The UPC will participate in the FLOIM project through the Centre for Sensors, Instruments and Systems Development (CD6), which is located at the Campus of the UPC. The activity of CD6 aims at creating value through innovation. Applied research developed by CD6 is defined in order the new knowledge generated, reaches the market as new products or new processes.

Almost 40 people with complementary expertise (Optics, Electronics, Mechanical and Software) work at CD6. This multidisciplinary combination is necessary to develop applications with a short time-to-market. The research results achieved at CD6 have led to the creation of several spin-off companies that manufacture and market new products in different sectors.

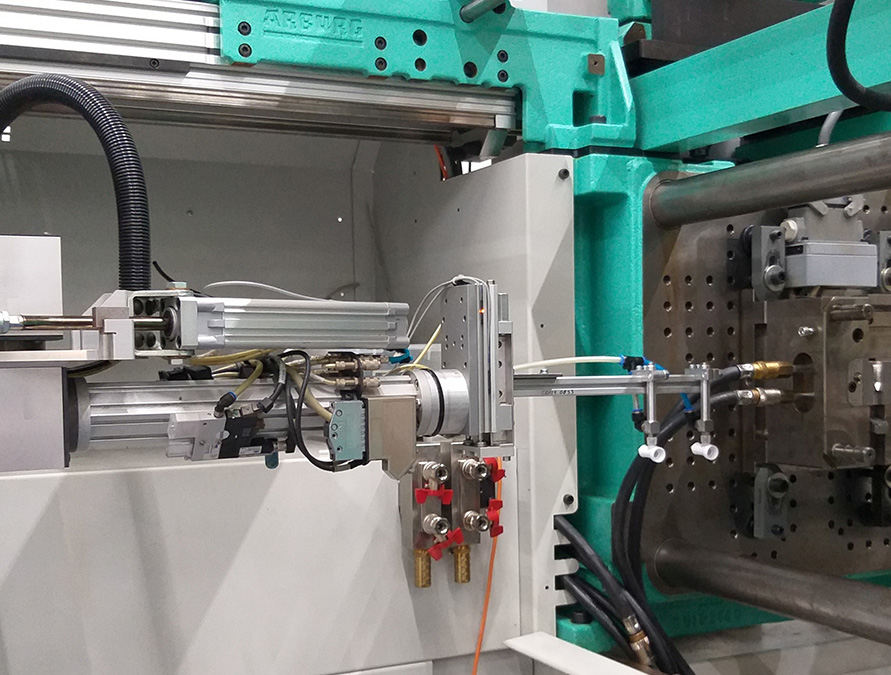

Promolding is a product development and injection moulding specialist in the Netherlands. Their unique selling point is that they are a knowledge centre, product development company and producer in one.

Their manufacturing department focuses on the production of high quality injection moulded parts from thermoplastic engineering polymers. They specialise in high tech industrial components and medical devices, which can be produced and assembled in their cleanroom.

Their product development team has extensive knowledge and experience with the unlimited design possibilities of thermoplastics, but is not limited to designing only plastic components.

They have a wide variety of well trained design engineers, mechanical engineers, polymer scientists, tool makers, injection moulding experts, production technologists and project managers.

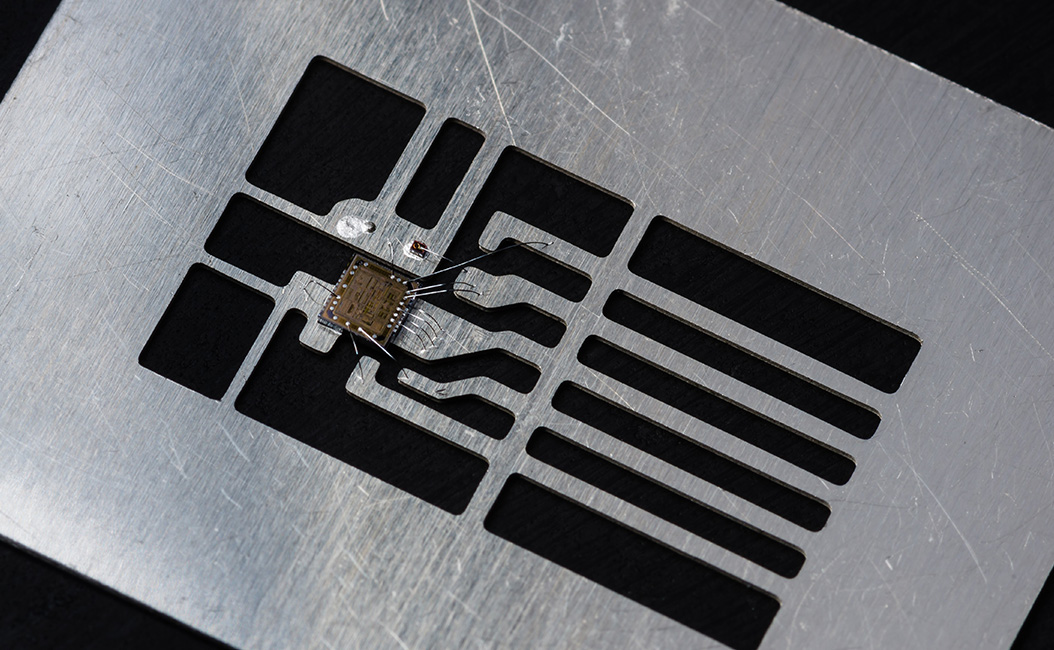

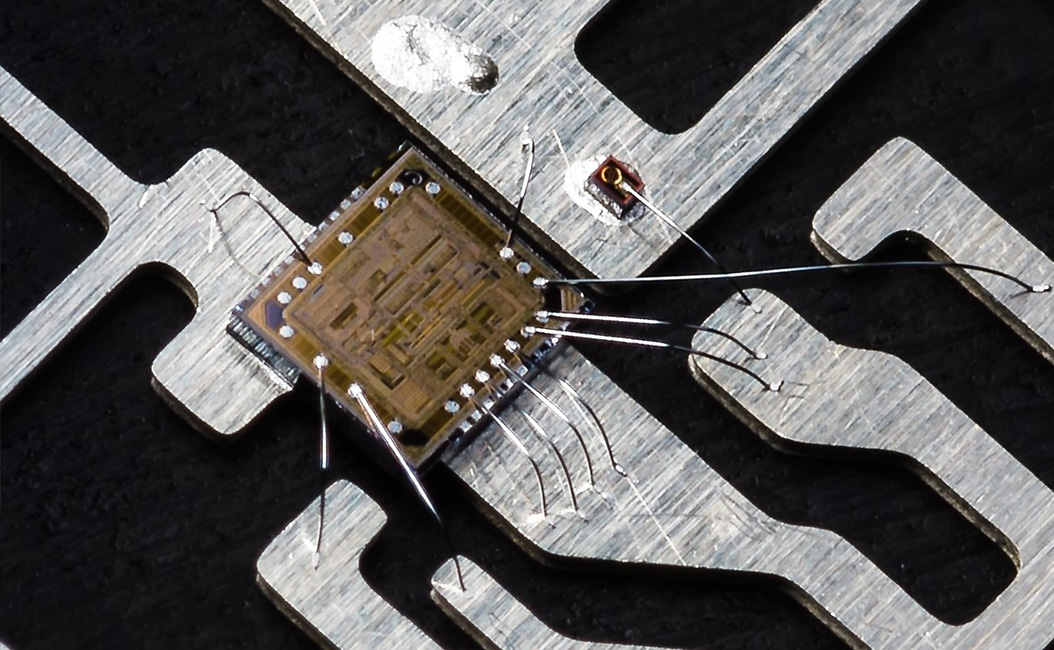

Hybtronics Microsystems S.A. located at Vitoria-Gasteiz (Spain) was founded in 1989 to design and manufacture thick film hybrids, electronic microsystems and sensors. Main markets are Industry, Automotive, Medical, Aerospace and Solar CPV. Company is certified ISO 9001:2015 and IATF 16949. Manufacturing is performed in clean rooms classes ISO7 and ISO8. Facilities comprise printing machines, trimming lasers, SMD line with vacuum reflow oven, die attach, bonding: Au ball and wedge bonding and Al wedge bonding, AOI, ICT, dispending robots and Automatic Test Equipments. Company also has specific facilities for dedicated products as automatic potting and testing line for ignitors.

Mondragon Assembly designs and manufactures systems and equipment for process automation. They integrate a wide range of commercial elements in their systems and develop tailor-made solutions to adapt to their customers' requirements providing the most profitable solution in each case.

Opto-electronic sector has been defined as strategic in Mondragon Group, because of growing forecasted for the coming years, and this is only achievable by means of advanced automation (robotics) and new manufacturing processes. Mondragon Assembly has started working in flexible automation and real time inline control based on NDTs with the aim of becoming a European technology supplier for high added value microelectronic sector.

FAGOR AUTOMATION is a company with great experience in the development and manufacturing of products for machine automation and control. It excels by its capability to develop software and the versatility of its productive process to offer solutions tailored to the needs of their customers. Historically, FAGOR AUTOMATION has focused their efforts on the machine-tool sector where they are one of the world leaders. FAGOR AUTOMATION career has been so successful thanks to investing efforts in R&D+i, dedicating more than 10% of its turnover to R&D+i.

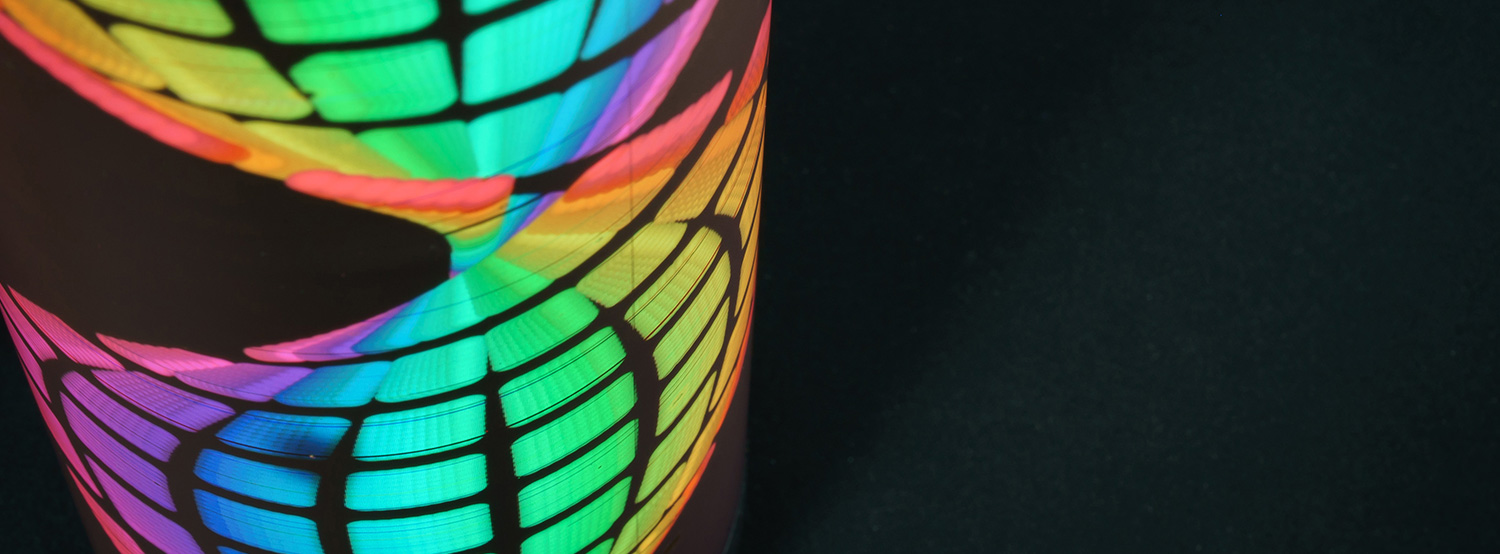

An important part of Fagor Automation product portfolio is the position measuring systems. Fagor Automation has been manufacturing high quality linear and rotary encoders using precision optical technology for more than 30 years. In order to ensure quality and reliability in all its products Fagor Automation utilizes the most advanced technology, testing and manufacturing facilities.

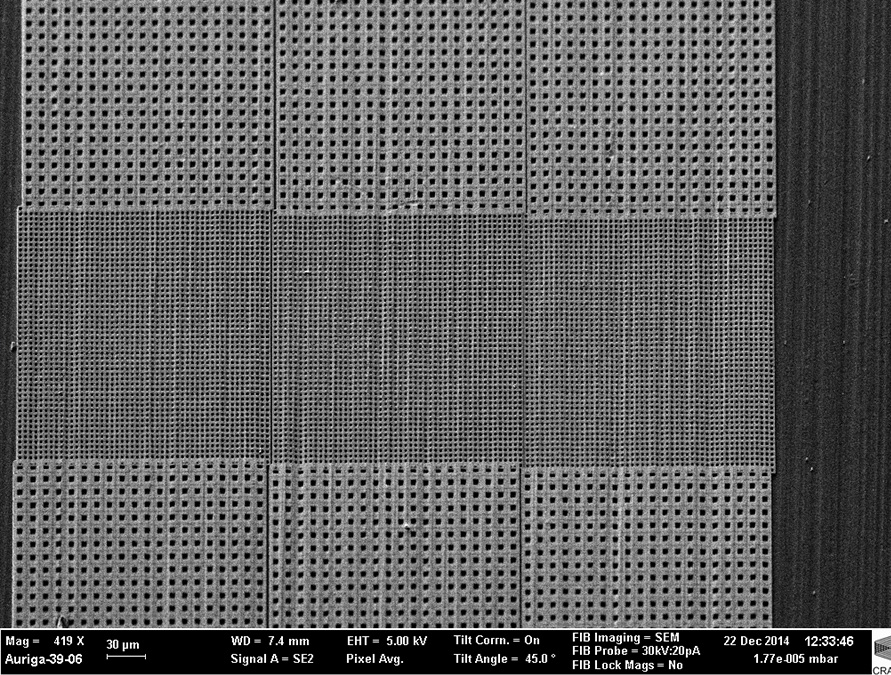

Adama Innovations is a start-up company commercialising a novel nanoscale patterning technology that allows rapid manufacture of bespoke profiles and shapes in diamond, DLC and other advanced hard materials. The company is a spinout of Ireland’s premiere university Trinity College Dublin, and was privately financed in 2014. Adama’s proprietary high performance patterning capabilities comprise flexible, simple, and cost-efficient methods to manufacture nanometer through micrometer and millimeter-scale diamond structures on wafers, dies, tools and other substrates. Current commercial products are in the MEMS space for wafer scale production of high performance diamond metrology probes. The company is also using the technology to introduce nano- and micro-structures to DLC coatings on injection moulding and nanoimprint dies. This high precision, high volume manufacturing technique lends itself to a variety of industrial applications such as medical devices, anti-counterfeit, holographic or decorative images in metal surfaces and micro optical components in glass or polymers.

FlexEnable has pioneered the world's first flexible electronics technology platform. Compatible with existing manufacturing lines, it's the key to truly flexible and cost-effective electronics over large and small surfaces. The core applications of this technology are glass-free, flexible displays and sensors that enable game-changing products across a variety of industries including consumer electronics, wearables, automotive, medical and security.

With a strong IP portfolio and a unique, scalable organic electronics manufacturing process, FlexEnable can rapidly accelerate customers’ route into plastic electronics and their achievement of a truly differentiated product offering. Customers include OEMs, component manufacturers and materials suppliers.

The Research Center for Non Destructive Testing GmbH (RECENDT) is an internationally renowned research centre that is highly successful in the field of material characterization and non-destructive material testing. RECENDT has a vast experience in different non-destructive testing methods, which range beyond classical NDT techniques. At RECENDT both fundamental and application oriented research is performed in the fields of Optical Coherence Tomography (OCT), Near Infrared spectroscopy (NIR), THz technology (THz), Laser Ultrasound (LUS), and Photo acoustic tomography (PAT).

As a leading institute for resource-efficient production within the Fraunhofer-Gesellschaft, with over 600 staff members, Fraunhofer IWU is an important R&D partner for the automotive/ vehicle, machine tool and mechanical engineering industries. Fraunhofer IWU has achieved an international reputation for developing efficient value chain and supply chain processes, particularly in the machine tool, vehicle and component production sectors. New recent research includes methods to combine manufacturing technologies and novel functional materials. Furthermore, the IWU services range from setting up digital infrastructures and tapping into data sources to conceptualizing and implementing data architectures in order to introduce modular solutions of Industry 4.0.

The institute is a member of EFFRA, the European Factories of the Future Research Association and of EARPA, the European Automotive Research Partners Association. Fraunhofer IWU is also an active player in Saxony’s smart specialisation strategy via the Vanguard Initiative.

Ceit‐IK4 is a non‐profit research centre that was created by the University of Navarra in 1982. Their primary mission is to carry out applied industrial research projects under contract, working closely with our clients' R&D departments.

Ceit‐IK4 promotes excellence in applied research by publishing non‐confidential results, disseminating scientific and technical knowledge in a variety of venues, and training doctoral students within the framework of industrial research projects.

Ceit‐IK4 seeks regular collaboration with companies in a range of sectors (railway, aeronautical, automotive, health, manufacturing, energy and environment) and strives to understand all aspects of our clients' business in order to develop high value added solutions through applied investigation projects. In addition to offering innovative solutions to our clients, Ceit‐IK4 trains young researchers who are preparing to join the labor market and add value to the production system.

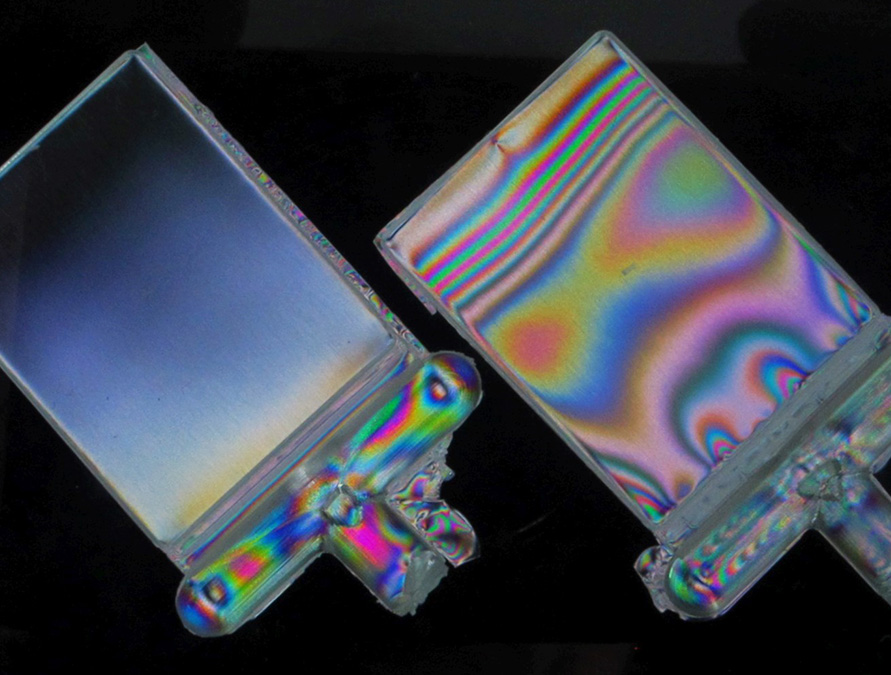

Simulacions òptiques S.L. (known by its registered brand SNELLOPTICS™) is a SME company founded in 2003 as a start-up of Center for development of sensors, instruments and systems (CD6) from UPC. SNELL activities focus on two main subjects: polymeric lenses for LED lighting and Optical Engineering.

SNELL has the capability to develop and manufacture products in optical engineering as a direct consequence of the company's origin, with highly qualified technical staff formed within the University. It continues to add highly qualified staff for sectors such as Automotive, biochemical analysis, visual optics, defense & security and general lighting.

Besides the Optical Engineering projects developed, SNELL is currently selling plastic optics in the Spanish market since 2012, with a market penetration of 1% over a total of 10 million units/yr.